The characteristics, properties, component composition, principles of creation, as well as the advantages and disadvantages of various court surfaces are described.

Tennis court surfaces

In 1909, the British company EN TOUT CAS, the first in the construction of clay courts, began to make a covering (surface) layer from a mixture of clay and tile chips. Tiled crumbs significantly improved the passage of water through the surface. The company gave the name “Fast-Dry Court” to its innovation.

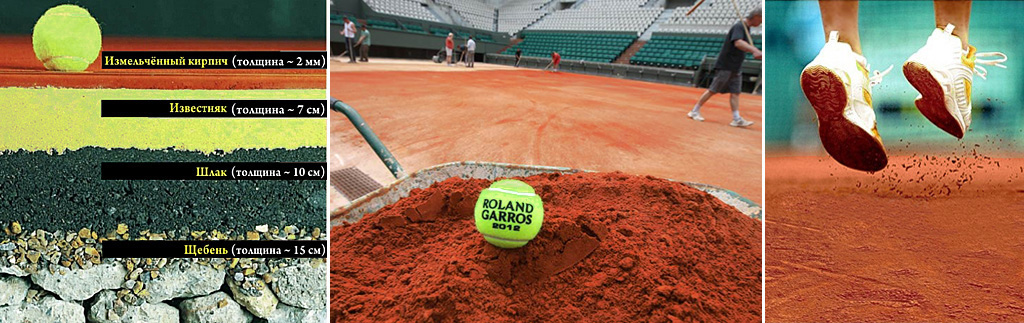

In 1927, Charles Bouhama proposed the use of limestone underlayment to improve overall drainage, as well as to improve the fixation and softening of the cover layer. This technology was used to build courts at Roland Garros in 1928.

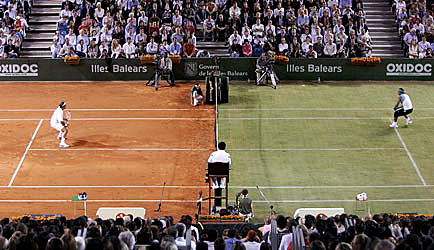

The left photo shows the laying of layers of soil covering the Roland Garros courts (fine gravel can be used instead of slag).

The thicker the top layer, the smaller its fraction and the more moistened it is, the slower the ball bounces. This feature is often used by the host side at the Davis Cup and the Fed Cup, when their team is weaker than the opponent, because. slow coverage does not make it possible to win balls with one or two strong attacking shots.

Unlike artificial turf (except artificial turf), the ground allows the player to slide over the turf (Slip Resistance) when braking – the player, as it were, drives up to the ball, preparing to hit.

Clay courts are currently red and green. The most common red soil (Clay Court or Continental Clay), which we usually call “tennisitis”.

“Tennisit” has the ability to quickly pass excess water through itself (in the event of rain) and at the same time retain the necessary moisture for up to 2-2.5 hours. The composition of tennisit includes crushed (powdered) red clay, brick (tiled) chips, slaked lime and special additives. For the manufacture of crumbs, semi-dry pressing bricks should be used, the distinguishing feature of which is the absence of sharp solid particles (the main difference between semi-dry pressing and plastic pressing is that the raw material is dried before firing, then crushed into powder followed by pressing at higher pressure).

It is “tennisit” that is used at Roland Garros (the unofficial world championship on clay courts). Despite the fact that the cover layer is quite thin, each year it takes about 850 kg of tennisite to backfill each court of the Roland Garros tennis stadium.

Tennis courts are the most popular in post-Soviet countries, Spain, Italy, Portugal, and France. There is a court surface – draining, where there is no clay, among other components. Such court coverage prevails mainly in Sweden and Germany.In Mexico, sifted crushed stone of volcanic rock is used as a crumb (Tepetate), and in the Crimea, because of its cheapness, pink marble sand.

The main feature of such courts is a soft surface and a slow rebound of the ball. It allows, unlike other coatings, to reduce the load on the joints and ligaments of the legs. The slow rebound speed of the ball characteristic of the ground (Surface Pace tests) makes it possible to better control the ball in preparation for the strike and keep it in play longer. By saturating the clay courts with water to varying degrees, the speed of the ball's rebound can be controlled.

According to experts, the temperature on the ground surface of a tennis court in hot weather is 20% lower than on asphalt or concrete surfaces. A comfortable microclimate arises above the clay court due to the constant moistening of the coating.

The disadvantages of clay courts include not always an even rebound of the ball (ed. – How and with what is the marking done on clay courts here).

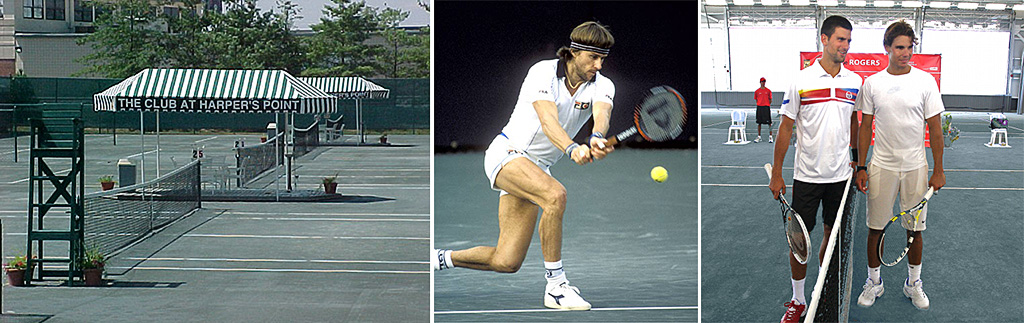

Green soil (actually it is gray with a green tint) “Har-Tru” (Har Tru) or “American soil” (American Clay) is similar to classic red, but due to the very fine crumb fraction (almost dust), it is denser, and therefore faster than red. Instead of brick chips, it uses a green basalt mineral (diabase is a volcanic rock) mined in the Blue Ridge quarry (Virginia), which is not processed, and is only crushed into a fine fraction.

The coating does not retain water, the top layer does not soften, and does not rise under the influence of negative temperatures. Thus, Har-Tru allows you to extend the season by 2-3 months. It can be used for both outdoor and indoor courts. Moreover, in the latter case, its use is justified by the fact that dust and suspension do not appear from it, which are inevitable when playing tennis.

This coating can be laid over asphalt or concrete. It has an unlimited period of use. The more green courts are used, the more even the rebound becomes. Har-Tru dries quickly and is easy to maintain. With the active use of the court for 6 months, no more than 400 kg of bedding is required (for red soil – 1.5-2 tons). For example, 1 worker is enough to serve 12 green courts (at least 4 people for red clay).

Courts based on Har-Tru, as a rule, have a slope for water runoff.

| In 1928, Henry Alexander Robinson, a New York court contractor, began introducing local Pennsylvania material in place of pounded red brick as part of tennis courts. The first part of the name he proposed to cover is his initials. The first green clay court was built in 1931 in Hagerstown, Maryland. From 1975-77, the US Open was played on green clay courts in Forest Hills, New York. |

More than 30 thousand Har-Tru courts have been built in 24 countries of the world.They are even available at the All England Lawn Tennis and Croquet Club in Wimbledon (ed.- 8 courts with green ground, 19 – grass, 7 – hard, of which 5 are indoor). Most popular in the southeastern United States. In 2004, the ITF allowed Davis Cup matches to be played on the Har Tru surface.

In the right photo, the new courts (four courts) on the roof of the National Tennis Center of Canada in Montreal were tested in August 2011 by Novak Djokovic and Rafael Nadal.

In 2012, the owner of the Mutua Madrid Open, Romanian Ion Tiriac, covered the courts with blue clay so that the color of the surface would be in harmony with the color of the title sponsor of the tournament, the insurance company Mutua Madrilena (more here).

At present, a ground top coat (of all colors) is sprinkled on top with crumb rubber or plastic, which can also be used in a clay crumb mixture (“tennisite”).

Characteristics of clay courts

13–20 – average;

100 – preferred level;

The advantage of the soil is: durability, ease of repair and renewal of the surface.

- mandatory watering of the court in the summer season;

- inability to operate for several hours after a downpour or prolonged rain;

- at sub-zero temperatures, the moisture in the limestone layer freezes and the coating swells, protruding plastic marking lines;

- spring rolling of the court with a skating rink 400-500 kg;

- the most expensive service.

Grass (Grass)

Grass (Grass)

| The first tennis courts were grassy, and the game was originally called lawn tennis (“lawn” from English – lawn, lawn). At the beginning of the 19th century, grass courts were mainly built in Great Britain, the USA, Canada, and Australia. At one time, three of the four majors (except Roland Garros) were played on grass (Wimbledon from 1877; US Open 1887-1974; Australian Open 1905-1987). To date, grass court tournaments are held at Wimbledon (ITF), Halle (Germany, ATP), Queens (just as Wimbledon is a suburb of London, ATP), Eastbourne (England, ATP, WTA), Hertogenbosch (Holland , Asia-Pacific, WTA), Birmingham (England, WTA), Newport (USA, Asia-Pacific), Stuttgart (Germany, ATP). And since 2017 in Antalya (Turkey, Asia-Pacific). |

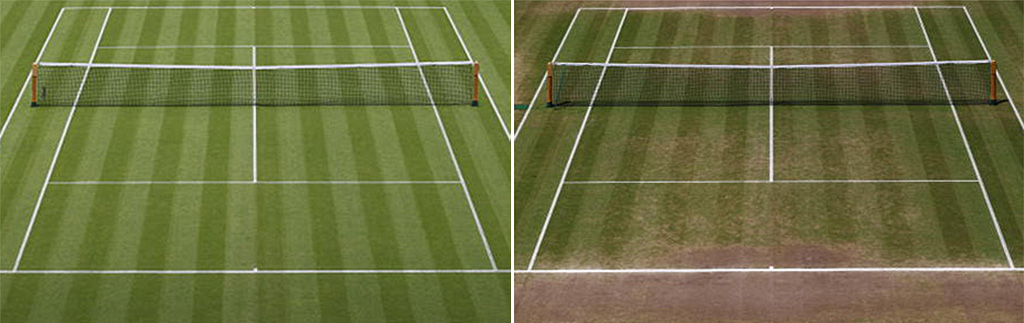

Grass is the fastest surface used in major competitions. Faster than grass, only some types of artificial turf for halls. The rebound is very low, and if you can change the rebound speed of the ball of other surfaces by adding various components to their composition, then you can change the rebound speed from the grass only due to the direction of growth of the blades of grass and their height. For example, on the courts of the All England Lawn Tennis and Croquet Club (Wimbledon), the grass is cut short – 8 mm (since 1995). But, nevertheless, the organizers of the tournament managed to reduce CPR, which allowed the king of the soil Rafael Nadal (Rafael Nadal) twice (2008, 2010) to win it.

So that the ball bounce is not even lower, the soil is kept dry throughout the game day (the grass is not watered).

On grass, the probability of incorrect rebound is somewhat higher than on other surfaces.This happens when the ball hits either a bump, or a large bush, or a crushed or trampled area.

The main disadvantage of turf is that its playability depends on the state of the grass. For example, by the end of the Wimbledon tournament, the courts lose half their grass cover.

7-time Wimbledon champion Pete Sampras spoke quite accurately about grass courts: “Wimbledon are two completely different tournaments. And it is played on the grass, only the first of them”.

The grass is grown in well fertilized and granular (sandy) soil. As for the cultivar, based on research conducted by the Yorkshire Sports Turf Research Institute (STRI), the courts of the All England Lawn Tennis and Croquet Club use Perennial Ryegrass, a hard-wearing, long-lasting grass. The removal of grass is carried out according to a special technology (see video below), which is kept secret. When the English are asked how to make a real grass court, they answer: “It's very simple. You need to take a special kind of grass and sow a leveled area with it. After some time, cover the site with a small layer of soil and sow the grass again. And so several times. As soon as the grass grows, it must be cut and watered every day for … 100 years. That's when you get a real court”.

During the Wimbledon tournament, after the end of each game day (approximately 21.30), the courts are watered and covered with a waterproof translucent cover (translucent – to allow daylight to penetrate). They cover it so that in hot weather the moisture from the soil does not evaporate, and in rainy weather the turf does not get wet. The cover on the central and first courts, where the coverage area is the largest, weighs about 1 ton.

Watering for each court is individual, and is determined by the condition of the turf, tested by STRI specialists, who measure daily throughout the tournament. In addition, at Wimbledon, the first Sunday is a day off for participants. On this non-playing day, the courts are flooded abundantly with water so that the grass can hold out until the end of the tournament. The approach is also individual – it all depends on the weather forecast for the next week. The volume of watering can be 3-10 times the daily amount. In general, up to 160 tons of water will be consumed during the two weeks of the championship.

The central court has an irrigation system of retractable sprinkler nozzles, controlled remotely. Other courts are watered by hand.

On each tournament morning, grass is cut, rolled (roller weight 200 or 250 kg depending on turf moisture) and updating the markup.

Grass court preparation

Also, only 60 years ago

For marking the court (painting lines), a special marking machine and paint based on acrylic polymer with natural filler and the addition of titanium dioxide (to increase durability) are used (approx.Avt.- earlier was used chalk or extinguished lime).

Herbal coverage in the halls is not used, although in the All-German Loun-Tennis and Croquet Club over the central court there is a sliding roof (It is planned to build a sliding roof over 2018 and above the court number 1).

It is quite effortful. Any awkward movement can lead to a fall. When you watch Wimbledon, then you draw attention as many players gliding on the grass, lose control over the movement (Prim.Avt.- Some players, such as Novak Djokovic, often uses sliding in the estate phase, others like Roger Federer, fit the ball, like a game of hard). The actual danger occurs when the legs are involuntarily sprawling in opposite directions (as in twine), causing an increased load on the knee and ankle joints and their ligaments. Especially the grass is dangerous if wet. Therefore, for the rapid drying, there should be a good drainage system (approx. There was a case when it was dried by a helicopter to prepare a wet court for the US Open-1969 finals (Video here).

Due to the need for special care (permanent watering and trigging, making fertilizers, protection against diseases), low wear resistance and restability, limited period of life of grass, as well as the need to constantly update lines of marking currently herbal courts are practically not built. True, as for the restability, the fact that the practice has shown, the courts of the All-German Club of Loun-Tennis and Crocket after Wimbledon 2012 were prepared for the 2012 Olympic Games in twenty days.

Dismantling of old jeep

The English daily newspaper Daily Mail leads (07.21.2018) the statements of the former Great British racket, and now a member of the Wimbledon Management Committee Tim Henman: Ideally, we would spend four matches per day on the central court and on the court number 1. But we must not forget that it is natural coating, grass. It must withstand 13 game days, and if kill her in the first week, then serious problems will arise.

Now the Wimbledon tournament invests a lot of money in creating a hybrid version – partly with artificial grass. This is used in football and rugby. We need to understand, with what percentage of artificial grass, tennis courts will look and function normally.

Several tennis generations ago in America, Australia, India had a lot of herbal courts, but they have extinct because of the need for serious care, due to the financial costs of this, due to the requirements for their quality .

Hard

Hard

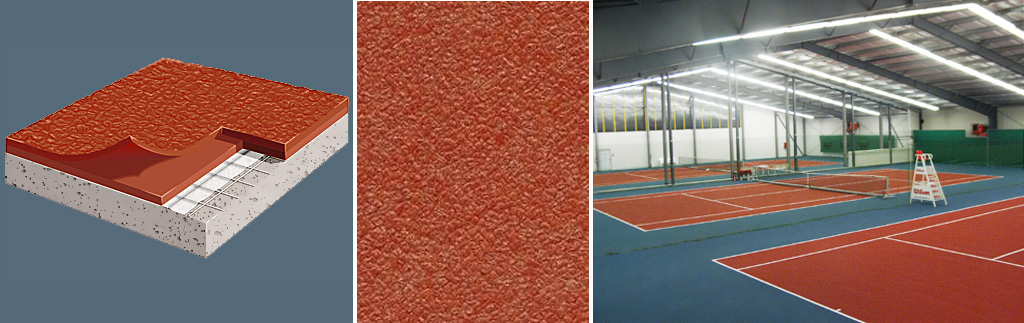

This is the general name of the type of sports artificial coatings, combining a number of coatings produced in different countries and having very significant differences (in functional properties, quality, prices). A tennis coating of HARD is a system of arrangement of acrylic layers to create certain technical characteristics of the cort.Therefore, a professional term for this type of sports coatings used in tennis: ″Hard coating system″.

- The base layer, which on open courts is an asphalt (asphalt concrete) base, and for closed courts – concrete. Possible emphasis on floor coverings from ″Regola.″ (Regupol) or ″Krabyburg Relastec″ (KRAIBURG RELASTEC) (these are coatings made of grinding rubber crumb), and even on a wooden base. In these cases, a special reinforcing grid is applied;

- Achillic leveling layer (Acrylic Resurface) of black color;

- one or more bulk softening colors (UNIRUBBER CUSHIONED COLOR);

- Finish layer (Precoat) with markup lines (Tex Line).

The bulk layers are made of rubber or rubber granules in combination of various fractions, and the binder material is an acrylic or other polyurethane emulsion. Mitigating layers can be manufactured from a bulk rubber or seamless regurga carpet (a fairly common option). The upper layer includes plated and ground quartz sand.

The technology of applying bulk layers provides for the minimum deviations of the cort plane from perfectly even. This is carried out due to the base equalization system and the method of layer-by-layer coating by ″Fill″ in perpendicular directions.

There are two main varieties of hard:

- ″Clean Hard″ – system ″Classic.″ With the 3rd layers (without softening layers): ACRYLIC RESURFACER (for filling the crack, creating a carrier layer) and two functional color finish layers (Acrylic Precoat). Used in professional tennis.

- ″Hard Cushion.″ – Systems: ″Comfort.″ with 6 layers (3 mitigating) and ″Premium.″ with 9 layers (6 mitigating). As an additional layer, a bulk rubber (Acrylic Cushion) is used or a combination of various rubber granule fractions. It is more comfortable for the legs, significantly reduces the load on the ligaments and the joints of the legs, lowers the risk of injury.

W. ″Clean Hard″ Another number of softening layers is possible. There are covers and with 8 softening layers.

The total thickness of the bulk layers is 3.5-5.5 mm.

The multi-layered coating in combination with the system of functional purpose of each layer eliminates the effect of the inhomogeneity of the base layer on the characteristics of the coating.

The number of layers, in principle, does not affect the high-speed characteristics of the court, the speed and height of the rebound is determined by the amount of sand in the top layer mixture. The smaller the sand, the more quickly.

Coating systems ″Hard″ Based on the speed and height of the ball rebound, classified by ″ITF CS 01/01″ (ITF SURFACE PACE RATING) for the following categories: ″Medium.″ or ″3″ – the average; Medium-Fast (″4″) – medium-fast; Fast (″5″) – fast (Methods of definition category here).

The fastest system is considered ″Deco Turf.″on which the members of the US Open played. This HARD system from the American manufacturer California Products Corporation was laid on the courts of the new National Tennis Center for the US Tennis Association. Billy Gin King in 1978 (Prim.Avt.- often this center is called Flashing Honey (Flushing Meadows) – by the name of the neighborhood in New York, in which it is located).

In 2020, a hard coating from the American company Advanced Polymer Technology was laid at the US Central Tennis Stadium (enters the Sport Group), which concluded an agreement with USTA for 5 years. Laykold is the world's only coating with vapor barrier, intended for hot and wet climatic conditions. This coating is also used in stadiums where Miami Open, Western Southern Open, New York Open is held.

In 1988, with the introduction of the National Tennis Center Melbourne Park in Melbourne, Australian Open began to be held on the system ″Rebound Ace.″that is a little slower ″Deco Turf.″. This is evidenced by a much larger number of protracted matches compared to similar statistics for corts at the US National Tennis Center in Flushing Meadows.

″Ribound Ace″ (Rebound ACE) – Pure Austrian invention. It used not acrylic, but polyurethane, fiberglass and crumb from the processing of automotive tires. Here's how it described this coverage Boris Becker: Under the hot sun, such a court becomes slippery as a lot, then viscous as a swamp. It looks like a game in hell. But experts argue that legs ″Vyazli″ Due to the thickness of the substrate of 8 mm, then began to make 4 mm.

Since 2008, Plexicushion, manufactured by California Products Corporation, has been laid on the corts of Melbourne Park. Similar system ″Plexipave IW in″ Covers and courts of the Tennis Stadium Indian Wells Tennis Garden in Indian Wells (USA), where BNP Paribas Open is held. These coatings are even slower, but more heat-resistant. The basis of its upper layer consists of latex with plastic particles (Avt.- It is interesting that California Products Corporation in 2013. Acquired a patent for the manufacture of the Rebound ACE system. It means neither she is so bad, and besides cheap).

Since 2020, the Australia's open championship began to spend on a hardboard system ″Greenset from the Spanish company GreenSet Worldwide (Prim.Avt. President and gene. Director Former Professional Tennisist Javier Sanchez-Vicario). This coating is used on Paris Masters in Paris, Swiss Indoors in Basel and at the Olympic Tennis Stadium in Rio de Janeiro. On it played at the outcome tournament ATP in the London O2 Arena.

Since 2020, as well as at the USTA National Tennis Center. Billy Gin King, Laykold is used in Melbourne Park.

| Hard at official tournaments began to be used since the mid-1940. In 1953, the American company California Products Corporation presented the first fully (100%) acrylic multilayer coating of tennis courts. |

Hard systems, with a rough surface belong to the discharge of coatings ″without slipping″. For such coatings, a somewhat different (from the classical) technique of working feet when approaching the ball is characterized.

- sufficiently high absorption of shock loads (Schlock Absorption);

- rebound stability ball;

- When installing a large number of softening options;

- Saving properties in a wide range of temperatures from + 50 ° C – 40С °,

- wide range of colors;

- coating mattness, excluding light glare;

- unpretentious in maintenance and does not require special care;

- high resistance to abrasion, fading, and durability (the first restoration of the top layer is required only after 7-10 years of operation).

- the most traumatic surface (therefore, tennis shoe manufacturers are constantly improving their models for playing hard);

- does not pass moisture;

- at high temperatures, a heavy unpleasant odor occurs;

- durability depends on the quality of the base layer, associated with a rather complex laying technology and the influence of weather conditions when applied outdoors.

Recently, hard has become the most widespread in the world.

Teraflex (Tarafleks)

Teraflex (Tarafleks)

It is a synthetic rolled multilayer coating, which includes:

- base made of concrete, asphalt, wooden floor;

- Soft backing of closed-cell foam or PVC foam, the thickness and properties of which affect the speed of the ball rebound (the pace of the game);

- 2mm textured vinyl top layer.

The top layer is coated on top with polyurethane, which provides ease of maintenance and protects against various marks, thereby extending the life of the coating. If the top layer is not treated with polyurethane, then special tennis shoes are required that leave no marks.

In order for the foot not to get stuck in the place pressed by it, which can lead to damage to the ankle joint during sharp turns of the body, the upper layer is reinforced with a fiberglass mesh.

The total thickness of the coating is 6.0-7.0 mm.

The teraflex structure contributes to a greater twisting of the ball after its rebound and evenly distributes the point load over the entire area. This coating is similar to a clay court in terms of ball rebound speed.

Two installation options are possible – permanent, with gluing to the base and welding, and temporary – with attachment to the base with double-sided tape.

The most common brands of this coating are: Tarafleks ATP, Tennis, Sport B. Of these, Tarafleks ATP has the highest coefficient of friction, which means a slower ball rebound. The equivalent of the coating is Graboflex.

| For the first time, teraflex began to be produced by the French company Gerflor. |

- energy absorption (damping) of impacts, ensuring the comfort of the game;

- ease of maintenance;

- no footprints left.

- it is intended only for enclosed spaces with a positive temperature;

- not allowed to be exposed to atmospheric precipitation and direct exposure to ultraviolet radiation.

Tocarpeting (Carpet)

Tocarpeting (Carpet)

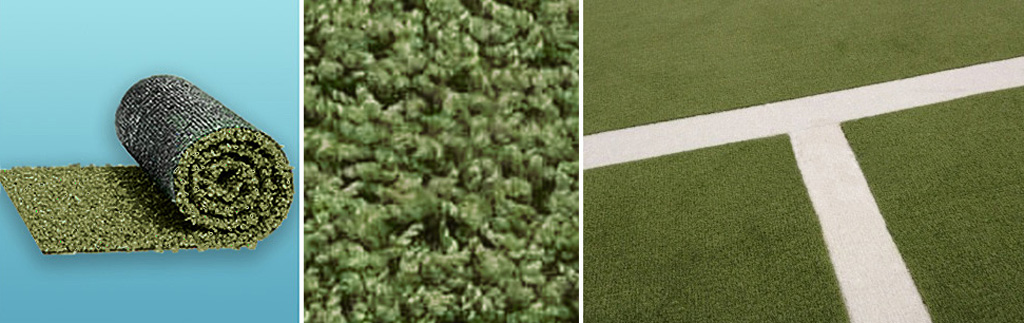

It is a synthetic carpet (tennis carpet) laid on a flat hard surface (asphalt, concrete, wood). It can be supplied in rolls or in modules. The seams are glued with a special technical device.

To “speed up” the court, as well as to allow the legs to slide when approaching the ball, carpet courts are covered with rubber granules.The use of backfill gives the surface a playful imitation of a clay court.

| The first carpet was called Sportsface. In the 1970s, the Supreme coating was most widely used. |

The bounce characteristics of the ball may vary depending on the thickness, structure and material of which the carpet is made. Since the surface is softer than hard courts, the speed of play on them is somewhat lower. Such courts are usually built indoors. For example, tournaments were held on the carpet: Paris Masters, US Pro Indoor, Kremlin Cup. Since 2009, the ATP and WTA have ceased to hold their tournaments on carpet. However, it is allowed when holding competitions under the auspices of the ITF, including the Davis Cup and the Fed Cup.

- predictable and optimal in terms of height and speed of the ball rebound;

- good grip with shoes, at the same time providing turns of the foot;

- small loads on the musculoskeletal system of tennis players.

- high cost;

- the influence of temperature conditions (as the temperature rises, the coating becomes softer);

- susceptible to damage and can fold (see video).

Artificial Grass (Synthetic Grass Tennis, Super Grass, Artificial Grass)

Artificial Grass (Synthetic Grass Tennis, Super Grass, Artificial Grass)

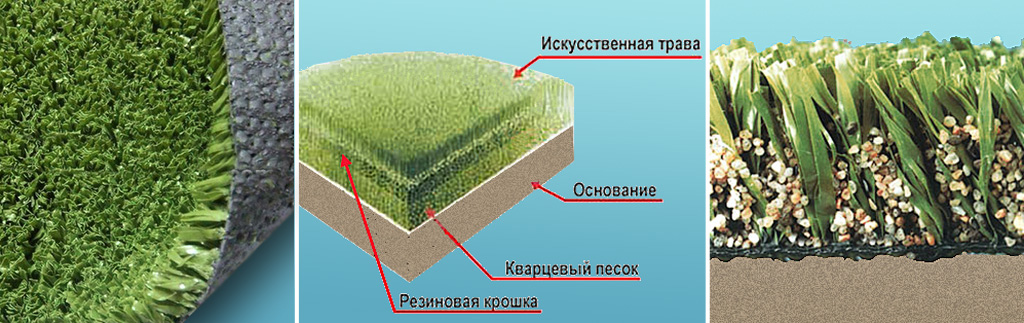

It is a type of carpeting laid on an asphalt or concrete base. It is produced using the “tufting method” technology: voluminous fibers imitating grass stalks are woven into a highly elastic base, which is then covered with latex. The pile is made of polypropylene, polyethylene, or a combination of both, which determines the durability and cost of the coating.

The differences lie in the type of fiber imitating grass and, as a result, in the service life, the height and density of the pile (the number of stitches per square meter), as well as the amount of backfilling with quartz sand or rubber (rubber) granules. The latter allow you to avoid skin burns when falling on the lawn. The infill is designed to stabilize the pile in an upright position and optimize an even bounce across the entire surface of the court. Depending on the thickness of the backfill, the height of the pile and the density of the coating are adjusted, which allows you to vary the speed of the ball rebound over a wide range: from slow to very fast. In addition, the hardness of the coating (ball rebound speed) depends on the degree of humidity of the backfill, for which this coating must be equipped with a water irrigation system.

Depending on the backfill, grass surfaces qualify for:

- backfill, with a pile height of 18-22 mm;

- semi-filled, with a pile height of 12-18 mm and greater density;

- non-filling, with a pile height of 8-12 mm.

Semi-filled and non-filled coatings require more demanding bases.

Playing on infill or semi-infill grass is closest in its characteristics to playing on natural grass or clay.

| Artificial grass for playgrounds (tennis, golf, baseball, football) was patented by the American T. Haas Frederick Jr. (T.Haas Frederick Jr.) in 1969, and its filling with sand – American Seymour A. Tomarin (Seymour A. Tomarin) in 1980. |

The markings are integrated into the coating directly at the factory, thereby reducing the number of joints in the coating.

After the first winter, the sand settles down, after which it can be blown off or swept away with foliage and other pollution without any problems.

- good sliding and turning capabilities, which ensures the comfort and safety of the game;

- small loads on the spine, joints and ligaments of the legs;

- hygroscopicity (drainage system of artificial grass allows games to be played 20 minutes after rain);

- all-weather and frost resistance (allows you to play at any time of the year);

- durability (wear resistance);

- not demanding in care and maintenance, and therefore does not require large expenses;

- fast installation (2-3 days).

The disadvantage is its high cost.

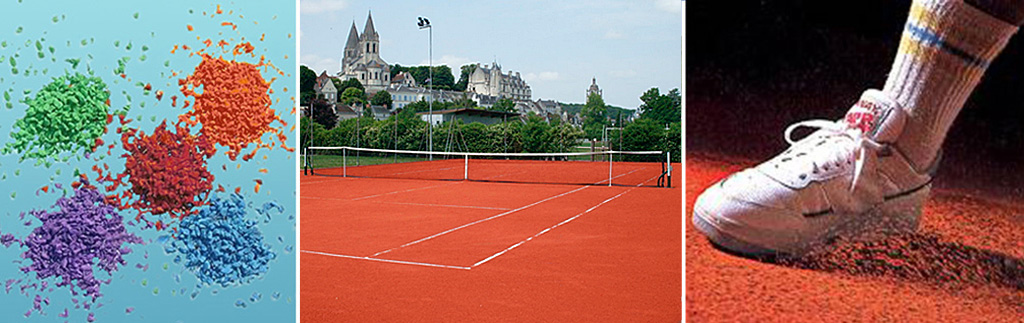

Synthetic Ground

Synthetic Ground

It is a monolithic coating with game characteristics corresponding to natural red soil.

- concrete or asphalt base;

- an intermediate (shock-absorbing) polyurethane layer, which foams when applied;

- covering layer in the form of polyurethane granules.

The variation of the ball rebound speed, sliding and impact absorption is carried out by modifying the intermediate layer.

- ease of care and recovery;

- no need for watering (compared to natural soil);

- high resistance to atmospheric influences (moisture, ultraviolet radiation, temperature fluctuations in a wide range);

- sufficiently high return energy of the coating, combined with reasonable absorption of impact energy;

- comfort of the game;

- the ability to set the desired rebound speed of the ball during installation.

Modular polymer coating (Modular Covering)

Modular polymer coating (Modular Covering)

It is made of high-impact polystyrene (PP) and due to the strictly organized dense structure of its surface, the coating ensures the correct rebound of the ball. The structure of the module has a mesh shape and its perforated surface does not retain water and dirt. The modular surface combines the qualities of grass and clay courts, but in terms of a set of properties (general dynamics of the game, contact of sports shoes with the surface, ball rebound) is closer to clay ones.

The coating is assembled from separate modules and joined together by self-jamming fastening elements without the use of glue and other auxiliary materials. It is easily mounted on any hard flat surface – concrete, asphalt, old worn-out hard courts (even if they have cracks). Mounting on compacted sand without a solid base is possible. When the coating is immersed in it, the sand fills and wedges each cell of the structural grid. This installation method is more complicated and requires additional equipment.But at the same time, the overall costs are significantly reduced.

Module (tile) size: 333×333×16 mm.

The main advantages of modular coatings:

- increased strength and wear resistance;

- noise absorption;

- ease of installation and dismantling;

- does not require care.

Drawback – Used for amateur level players.

(aut.- In the history of tennis there were also exotic coverings. So in 1963. The Indian Davis Cup team hosted Americans in Bombay on Cricket Club of India courts, which were made from cow dung. However, the specific smell did not prevent the US team from winning 5-0. ).