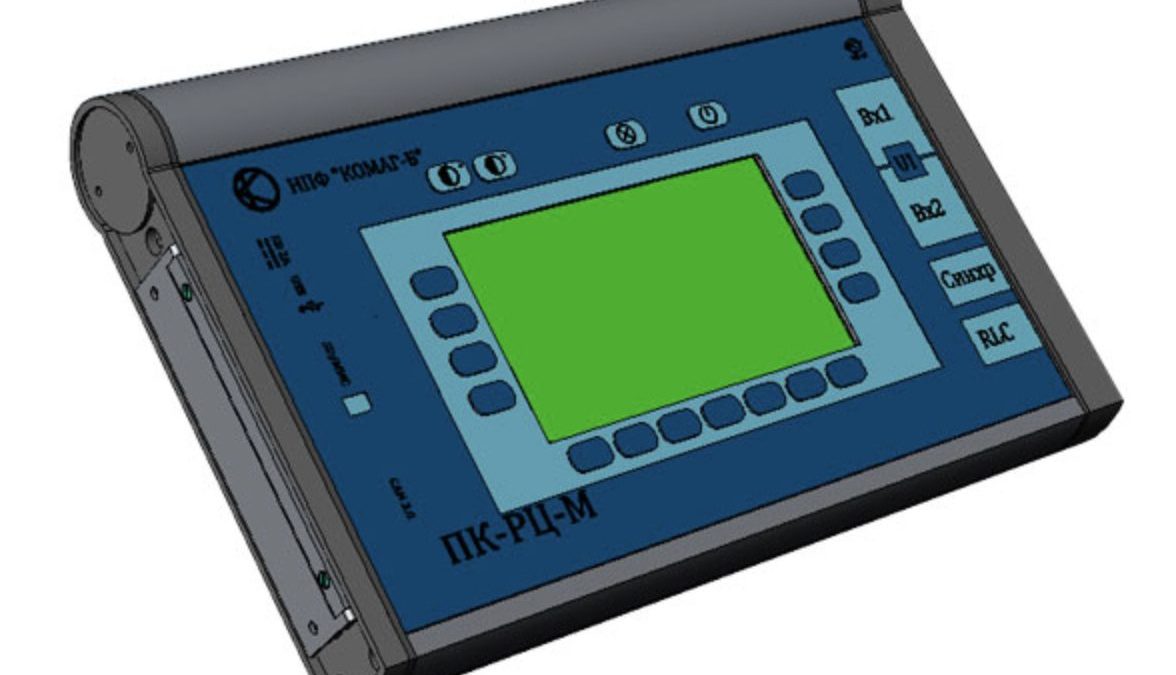

Products The device combined to measure rail chains multifunctional is designed to measure alternating and constant voltage, current force, signal frequency

Products

The device combined for measuring rail chains multifunctional Designed to measure alternating and constant voltage, current force, frequency of alternating current signals, resistance (including complex), capacity and inductance,

Specifications of code signals. There is support for measuring the resistance of the ballast.

• The list of signals present during the measurement is automatically determined. Measurement of code signals (ALS-H, ALS-EN, CRL) is accompanied by a code decoding. Any signal can be viewed on the oscilloscope cleaned from other signals.

• Connecting an external differential inductive sensor and current ticks. Suppression of industrial frequency interference is ensured. • The input range is expanded to 5 orders, which makes it possible to measure the signal from 1MV to 400V with the desired accuracy, and the increased dynamic range allows you to measure weak signals against the background of strong interference.

• Measurements produced in the range of mean-of-mean-square values create real prerequisites for the implementation of the principle of measurements in devices in the SCB devices.

• The device has two galvanically unleashed measuring inputs, as well as the input of external synchronization.

• The presence of an additional entrance allows you to organize the measurement by event. Which in combination with a large container archive (limited by the volume of removable non-volatile media – MMS memory cards or SD volume to 4GB) allows you to use the device as a black box. It is also possible to carry out measurements at specified time intervals by built-in hours.

• The USB port allows not only to transmit data and update the software, but also charge, supplied in the kit, Li-Ion battery.

• The device is certified and included in the registry of measuring instruments made to use in Russian Railways in the section Measurement tools applicable in alarm and communication.

Cable for measuring currents Designed to measure existing currents.

Voltage Measurement Cable Designed to measure the existing voltage.

Cable for connecting to a computer Designed to transfer measurement data via USB interface to a computer, to update the PCRTS-M software, as well as to recharge the battery of the device.

Year of the start of production 2011.

Temperature Range from -20 ° C to + 50 ° C, relative humidity up to 90% at a temperature of 30 ° C.

Overall dimensions of the device : no more than 267x168x37mm. Mass of the device : Not more than 1.4 kg.

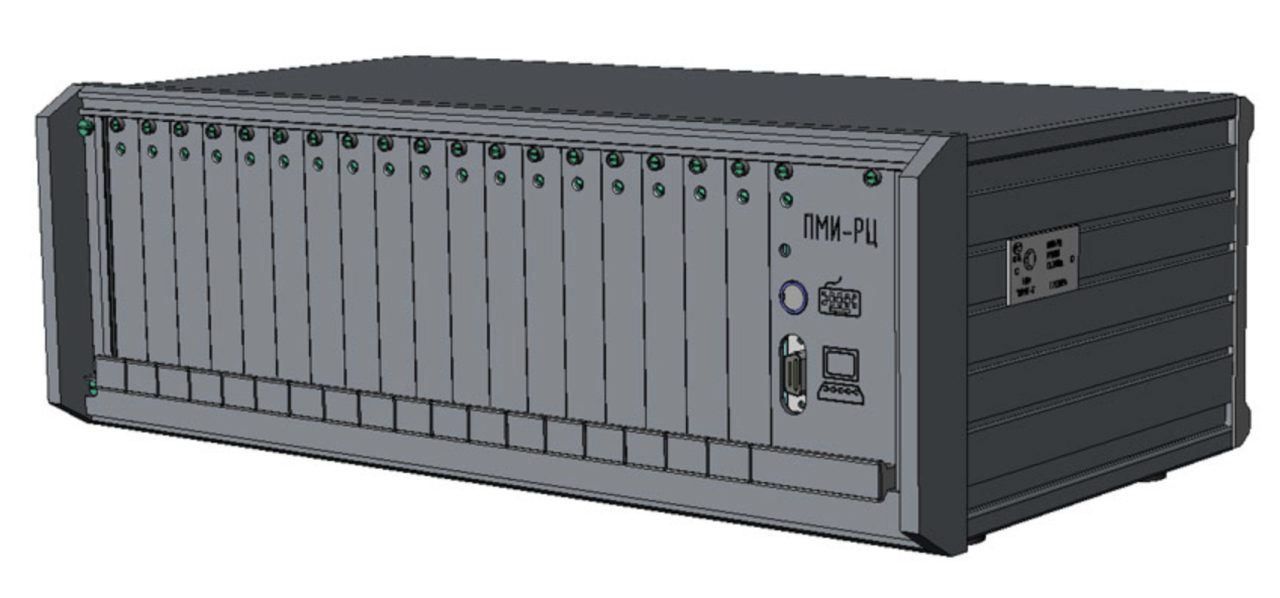

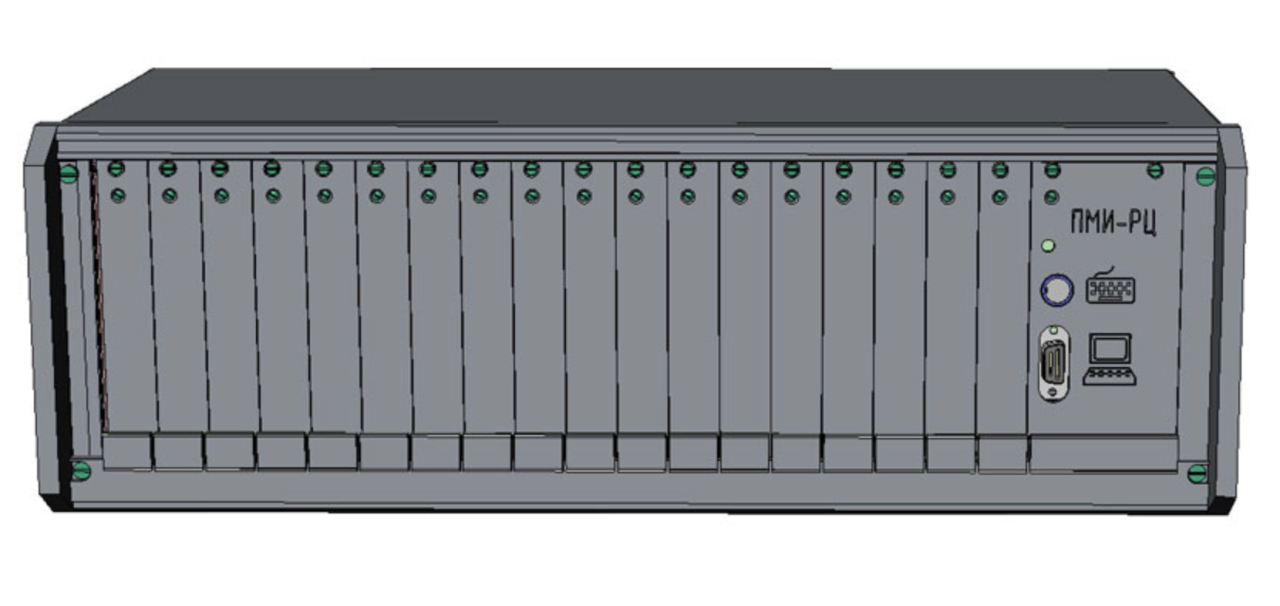

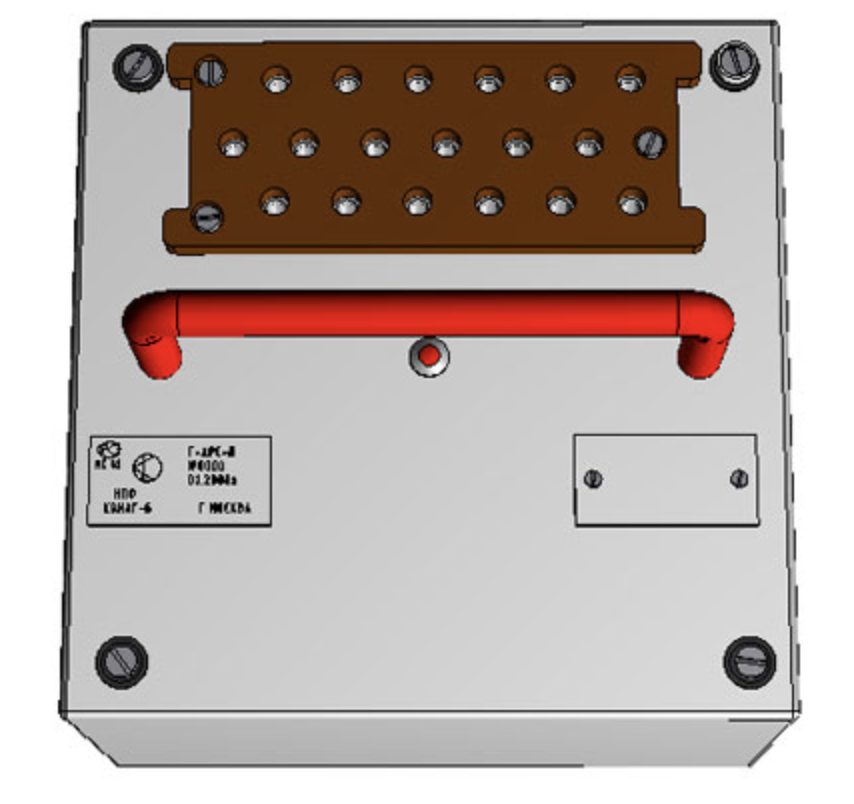

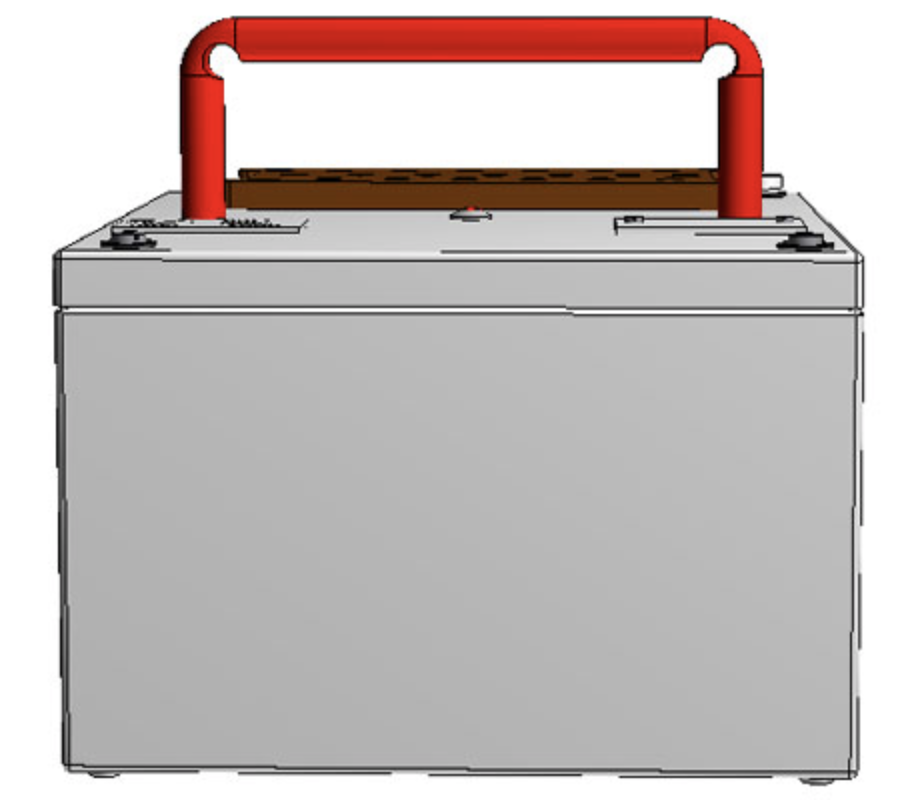

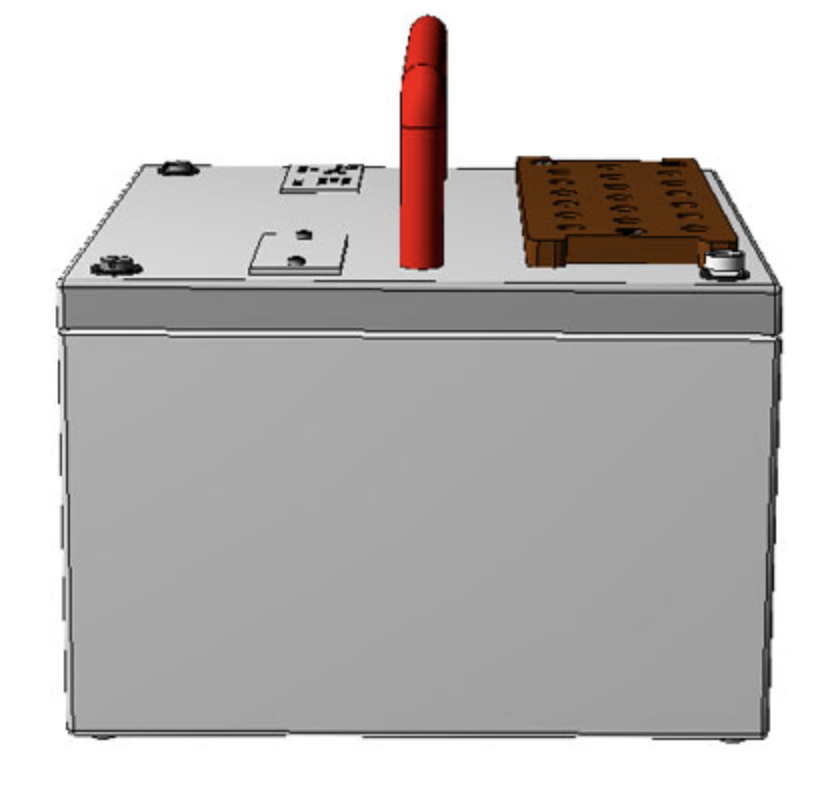

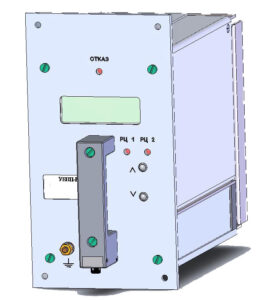

PM-RC

Converter Multichannel Rail Chains Measuring Signals Designed for measurements of the parameters of the signals of the KRL, TRC 3, ALSN and ALSEN in the process of operation of the ABTC-M automotive system.

PM-RC allows you to measure 36 galvanically unleashed channels:

• Sinusoidal alternating current voltage from 0.0025V to 300V with an error of ± 2.5%,

• Signal frequency of alternating current with an accuracy of ± 1Hz,

• voltage of alternating current of complex shape with an error of ± 4%,

• The voltage of the carrier amplitude-manipulated ALSN signals (excluding pauses) with an error of ± 4%,

• The frequency band and carrier frequency of signals of complex shape.

For each of the channels, a separate measurement of the signal of each type is performed. Measurement results are transmitted over the CAN 2.0 interface.

In the ABTC-M computer on request. It is possible to autonomous measurements on the instrument with a manual keyboard and monitor.

Generator mode – Nonsense.

Year of the start of production 2004.

Temperature Range from -5 ° C to + 50 ° C.

Automatic speed control generator Designed to operate in the system of automatic speed adjustment (ARS) of the movement of the trains of the metro.

The built-in self-diagnostic system with access to the computer via the RS-485 interface allows you to monitor the output frequency and voltage, the temperature inside the case, and also reports the malfunction of the instrument.

Installed on the regiment of the tripod.

Generator mode – Continuous.

Year of the start of production 2002.

Temperature Range From + 5 ° C to + 40 ° C, relative humidity up to 80% at a temperature of 25 ° C ± 5 ° C, vibration in the frequency range from 10 to 100 Hz with acceleration to 1G.

Signal Control Subatition Designed for diagnostics up to 16 shooting transfers.

The subsystem is designed both for use as part of the Metropolitan, and for self-use as a diagnostic means of switching transfers. The PKSS provides continuous tolerance control of the translations of the arrows and gaps up to 16 shooting transfers, relay blocking layout on the layout and indicating information about the current state of the arrow transfers and their faults on the display device.

The mode of operation of the subsystem – Continuous.

The subsystem consists of:

• Arrow signals control device (GRS),

• Arrow Signal Measurement Device (UIS),

• Device blocking layout on the layout (UBRM),

• Arrower Signal Display Device (WOSS),

• Device control of the spit (UCO),

• Sensor of the position of the spells (DPO).

Arrow signals control device: Provides management and data exchange with all PCSU devices;

Device measuring shooters: Provides digital processing of current sensor signals for each phase of the electric motor (when the corresponding threshold device is triggered) and transferring the measured current to the interface.

Device blocking layout on the layout: Provides control of solid-state relays for relay blocking by commands from the interface.

Arrow signals display device: Provides display information about the current state of eight-time transfers from the USS by the RS-485 interface.

Speed Control Device: Provides digital processing of signal sensors (DPO) signals and transmitting information about the measured gap over the interface.

Sensor of the position of the spells: Provides measuring the gap of the adhesive adjustment to the frame rail in the range from 0 to 6 mm.

Year of the start of production 2004.

Temperature Range from + 5 ° C to + 40 ° C and relative humidity up to 90% at a temperature of 25 ° C.

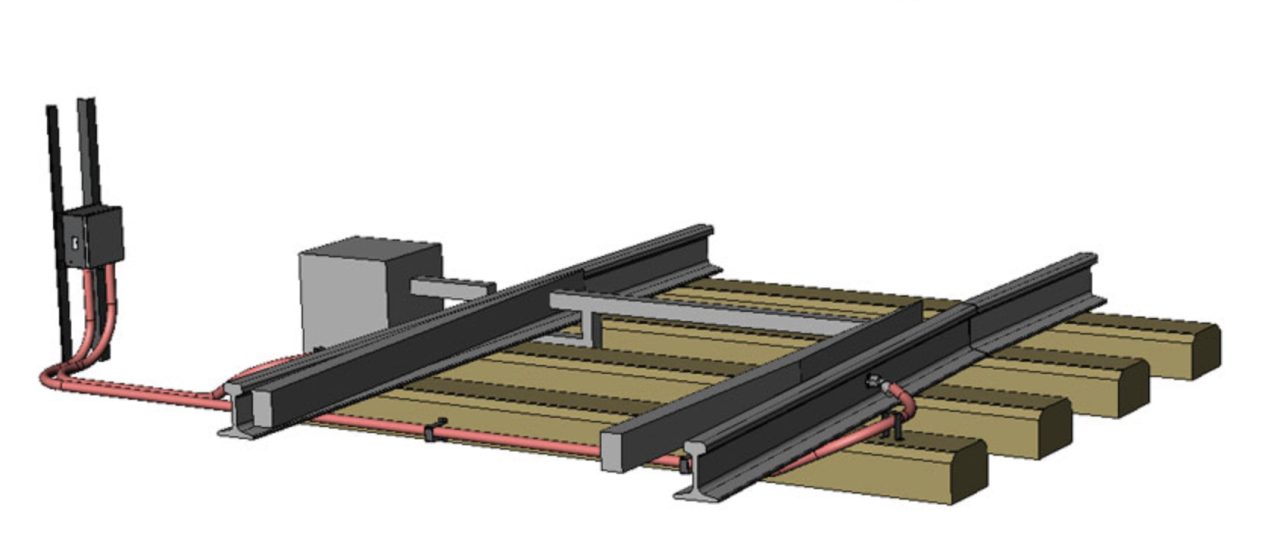

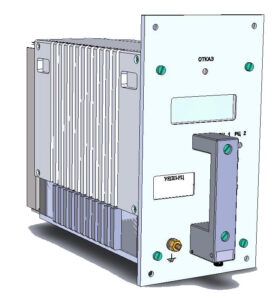

UPP-RT

Device Single Reception – Transmitter (UPP-RC) Designed to operate in automatic speed control systems (ARS) Metro Train Movement. It is installed both on the supply and relay ends of the rail chain. Installation:

– on the Nutritional end Performs the functions of the ARS signal generator main and, if necessary, the warning frequency with a face value of 75, 125, 175, 225, 275 (including CAO), 375 Hz, SIGNAL TRC with a nominal 420, 480, 565, 720 and 780 Hz with frequencies Modulations 8 or 12 Hz, and a single-channel receiver of signals of the TRC;

– on the relay end The UEPP RC performs the functions of a two-channel receiver of the signals of the TRC and the SIGN generator of the main and, if necessary, the warning frequency with a face value of 75, 125, 175, 225, 275 (including CAO), 375 Hz.

• The range of output voltage of the ARS signal from 15 to 170V, the signal of the shopping center from 3 to 60V at the maximum output power of the UPP-RC 250W.

• SIGNAL TRA is limited by the spectrum. Smooth turning on and off signals ARS allows you to reduce the effect on the reception of the SIGN signals on its own and adjacent rail chains. For each received SHIP signal, an individual adjustment coefficient is established, which makes it possible to abandon the use of external equalizing transformers.

• For ARS signals, it is possible to specify the internal resistance of the generator, which allows you to stabilize the current ARS rolling stock without increasing the dispel power on the external resistor.

• The presence of an additional entrance allows the use of UPP RC on isolated joints, while providing not only the operation of two adjacent rail chains at once, but also the control of the junctions of both relay and the supply end of the rail chain.

• Active COSF Corrector allows you to reduce the requirements for the power source relay.

• The interaction of the WEPP RC with top-level systems is possible both by means of a relay interface and through an electronic interface (according to three CAN-tires).

The device is produced in three modifications:

• UPP-RC-01 with relay and digital interfaces for installation on the host through Fastening panel (UPP RC-PC);

• UPP-RC-02 With a digital interface for installation in a 19 cabinet (7 devices on the 6U height shelf) through Corpus Group UPP-RC-02;

• UPP-RC-03 with a digital interface for installation in 19 cabinet (6 devices on the 6U height shelf) through Corpus Group UPP-RC-03;

Generator mode – Continuous.

Year of the start of production 2016.

Temperature Range from -20 ° C to + 40 ° C, relative humidity up to 100% at a temperature of + 25 ° C.

basic information

On issues Order devices Production of LLC NPF Commag-B must be written by mail: [email protected]

On issues warranty or current repair Devices of production of LLC NPF KOMAG-B must be written by mail: [email protected]

Contacts

The address:

115201, Moscow, Kotlyakovskaya ul., D. 3, p. 14

Phones:

89104386064 – those. the Department

Opening hours:

Monday-Friday: 7: 00-16: 00 – those. the Department

Monday-Friday: 11: 00-19: 00 – Accounting